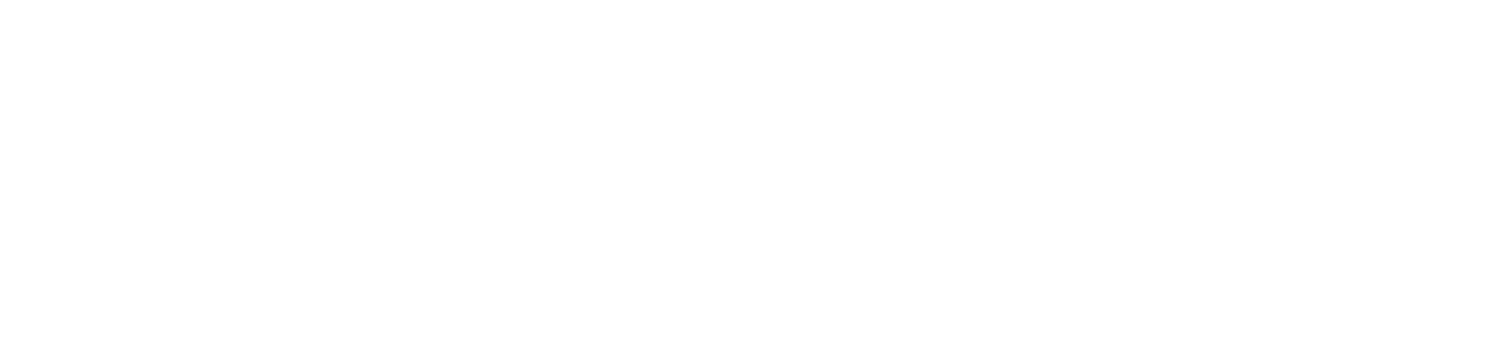

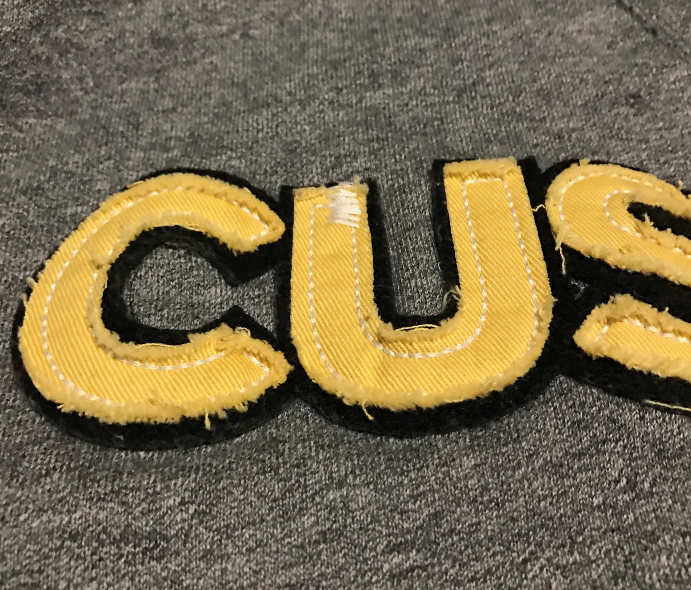

Appliqué is the reason I decided to start my own company. I used to work for a company that helped produce appliqués for Abercrombie & Fitch, Hollister, pro sports teams and many other large companies. I learned everything about fabric type, how the laser cut the fabric, unique stitch types and how to give the appliqué an authentic look through finishing. I use two main styles when building an appliqué- vintage/rustic & clean/sporty. The style you are looking for will determine the fabric type, stitch type, layering and finishing.

Fleece programs work best for appliqué from my experience, but sport jerseys, outerwear, and polos are some of the top secondary categories. Using appliqué on hats gives a nice touch for creating a unique look.

For those of you who own lasers, allocate time to figuring out how to streamline design and development so that they catalyze a smoother production process. Appliqué needs to be sold by you to the customer. Emphasize cost vs value. It’s a unique piece that has great retail appeal.

For those of you who don’t have a laser or don’t offer embroidery in house, I would suggest partnering with another manufacturer to offer their appliqué services to your customer. You can manage the relationship and ask the other manufacturer to give you a distributor discount so you have some margin.

Whether it’s standard felt lettering, tackle twill with zig zag stitch, or double-layered Bedford twill with distressing and repair stitches, appliqué can cover all audience types.